The Poulterra Platform

A scalable, sustainable agricultural platform supported by industry leaders — explore how it works with our proven process.

Growers

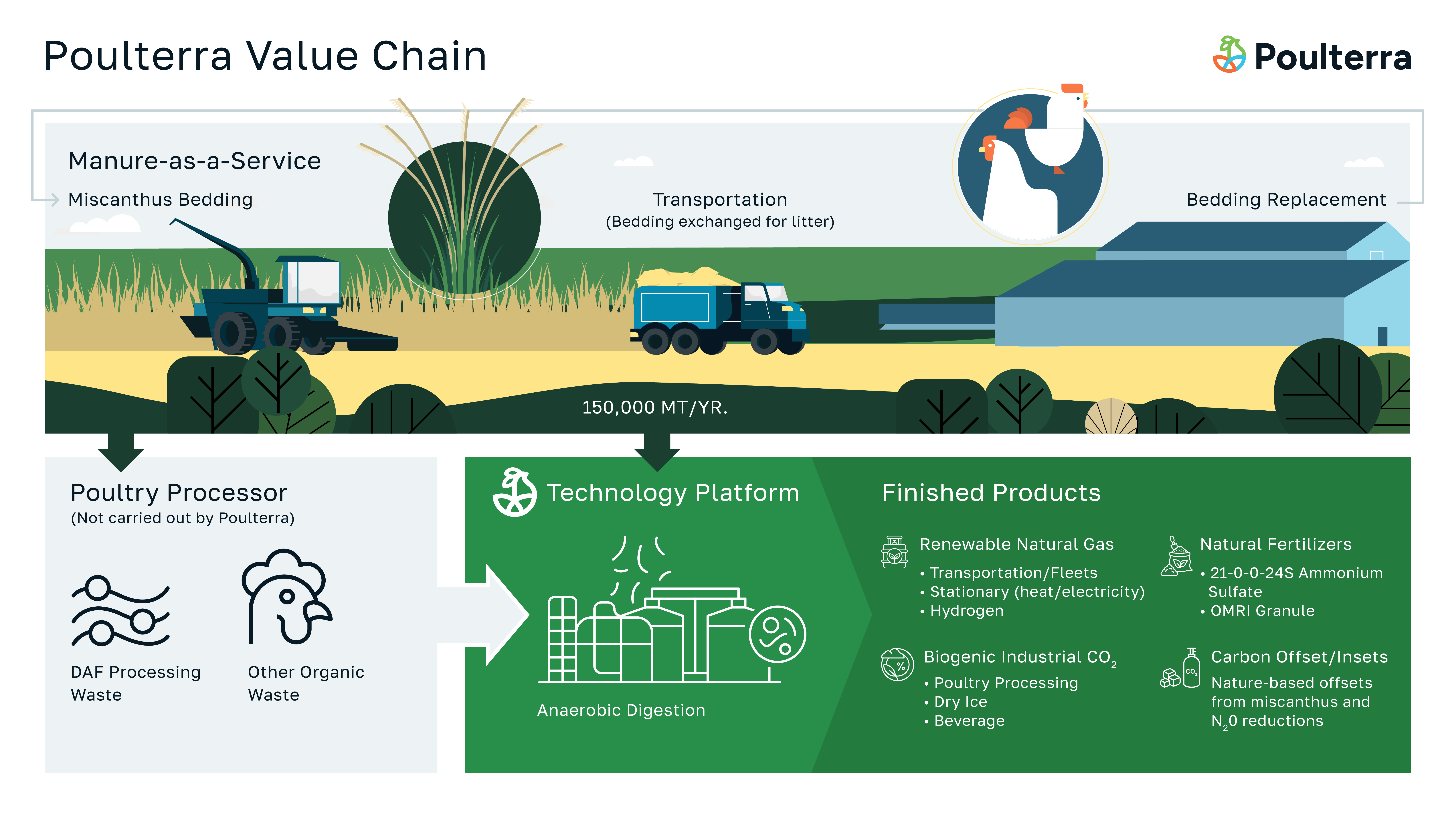

In the U.S., miscanthus as a bedding product is well-established, proven to be the highest quality, most sustainable bedding product in the market.

Poulterra supplies growers with miscanthus bedding annually in exchange for the previous year’s poultry litter.

Poulterra™

Our system processes poultry litter using anaerobic digestion to produce renewable natural gas (RNG), CO₂ and dry ice, and organic, sustainable fertilizers.

With a proven commercial scale technology platform, Poulterra is set to lead some of the largest animal waste to RNG projects in the U.S. with significant project and platform scale advantages.

Integrators

By creating large-scale litter to RNG production, we reduce environmental risk by eliminating litter from being spread on fields.

Decarbonize across the supply chain to make food more sustainable and affordable, while reducing operating risk.

An Industry First Bedding and Litter Solution for Growers

Last year’s poultry litter can be exchanged for carbon-negative, plant-based bedding at no cost. Poulterra is the first company to standardize bedding and litter management by providing a highly effective bedding product for growers on a predictable cleanout frequency. Our MaaS platform can be scaled across processing facilities to drive greater insights into performance, leveraging commercially proven refining technology to convert miscanthus litter into higher-value products including low-carbon RNG, fertilizers, industrial CO₂ and dry ice.

Unprecedented Scale from Poultry Waste to Renewable Natural Gas

Our projects represent the largest animal waste to RNG initiatives in the U.S., each capable of generating over 600,000 MMBTU’s annually. With strong support from the poultry industry and a robust pipeline of projects being developed, we are ramping up to significantly increase the overall level of industry sustainability, while driving down emissions through the production of low carbon fuel. RNG from our efforts can provide poultry integrators a way to reduce tailpipe emissions and lower commercial trucking costs. It’s one more way we are working to make poultry more sustainable.

Natural, Critical Inputs for Poultry Processing

CO₂ and dry ice shortfalls often result in plant shutdowns. Poulterra’s Manure-as-a-Service platform creates a scalable, local supply of biogenic beverage grade CO₂ and dry ice, positioning us as a key supplier. The circular nature — selling CO₂ and dry ice back to poultry integrators for use in processing systems — results in a sustainable, locally-produced product capable of reducing the typical emissions related to shipping and eliminating the use of CO₂ in poultry processing from fossil sources.

Upcycled Fertilizers for Sustainable Food and Feed Production

The climate crisis has driven regenerative agricultural practices and bolstered consumer demand for sustainable products to the forefront. Poulterra’s natural, nutrient-balanced fertilizers improve soil health, increase water retention and infiltration, reduce soil erosion, increase soil carbon levels, and help reduce Scope 3 emissions in the food and animal feed industries by displacing synthetic nitrogen usage.

Partnering with Industry Leaders

Miscanthus Production and Large-Scale Renewable Project Development

Today in the U.S. poultry industry, the ability to secure a stable supply of litter is challenging without a MaaS platform. Poulterra is the first to minimize this merchant risk through long-term, fixed-price feedstock contracts and RNG offtakes, in addition to qualifying for the EPA’s D3 Renewable Identification Number credit program.

These critical attributes allow for more infrastructure and project financing, improving the overall project viability. Explore the benefits of our approach and proven commercial-scale technology:

- Vertical integration driving highly differentiated advantage

- Some of the largest animal waste to RNG production projects in the U.S.

- Ownership includes the world’s largest miscanthus producer

- Miscanthus IP: 6 genetic plant patents and 3 equipment patents

- Predictable cash flows and diversified revenue streams

- Ability to execute with a highly financeable model

- Rapid scalability of platform with strong competitive barriers to entry

- Significant emissions and nutrient reductions

Platform Benefits

Poulterra creates partnerships across the supply chain with solutions for growers, integrators, local communities, and the environment.

Partner with Poultry on a Long-Term Basis

Standardize operations and performance

Solve Local Environmental Risks

Innovation Beyond Poultry Farm Waste Management

CO₂e emission reduction.

Uniquely reduce CO₂e emissions across the poultry supply chain by sequestering CO₂ in the roots of miscanthus, minimizing N₂O emissions with more frequent house cleanout cycles and avoidance of land applying litter, and displacing various fossil sources.

Critical emissions tracking.

Measure all inputs and outputs to track critical emissions data across the poultry supply chain. Through the MaaS platform, we provide our stakeholders detailed, third-party verified carbon accounting data that can be utilized for sustainability metrics and planning.

Nutrient reduction.

Significantly reduce the chance of nutrient runoff by removing litter from being spread on fields and planting miscanthus buffer strips along watersheds. We quantify nutrient reductions for companies and create opportunities for added revenue through nutrient credits and land rental for farmers.