Poultry Today

That’s where Poulterra™ comes in.

In the Industry

Solutions in Sustainable Poultry Farming

It’s time to maximize performance and sustainability.

Bedding made of wood shavings not only comes at a high cost, it’s also subject to declining domestic supply. At the same time, disposing of litter in condensed areas of poultry production is limited to spring and fall crop cycles, and often has nutrient application limits and environmental liability risk.

Poultry growers lack options, and the industry continues to see delays in cleaning out poultry houses. This further reduces operating and performance metrics in raising birds and lowers the overall efficiency of the system.

It’s time to unlock the value in poultry litter.

Poultry bedding is expensive and difficult to source, while selling litter is becoming more and more challenging to dispose of. Today, growers need cost-effective bedding and an environmentally-friendly home for their litter to be incentivized to clean out.

Developers seeking to process poultry litter need to secure a ratable supply of bedding that can be sourced on a long-term, fixed price basis. The bedding must also be free of wood products since their presence would render it ineligible for generating a Renewable Identification Number (RIN), the carbon credit created for producing renewable fuel under the EPA’s Renewable Fuel Standard.

It’s time to innovate at scale with a proven technology platform.

There are limited, proven technologies to process poultry litter into renewable sources at scale, few of which operate in North America today. Without a proven refining technology, securing project financing can be extremely challenging.

Poulterra's Closed Loop Waste Management Platform

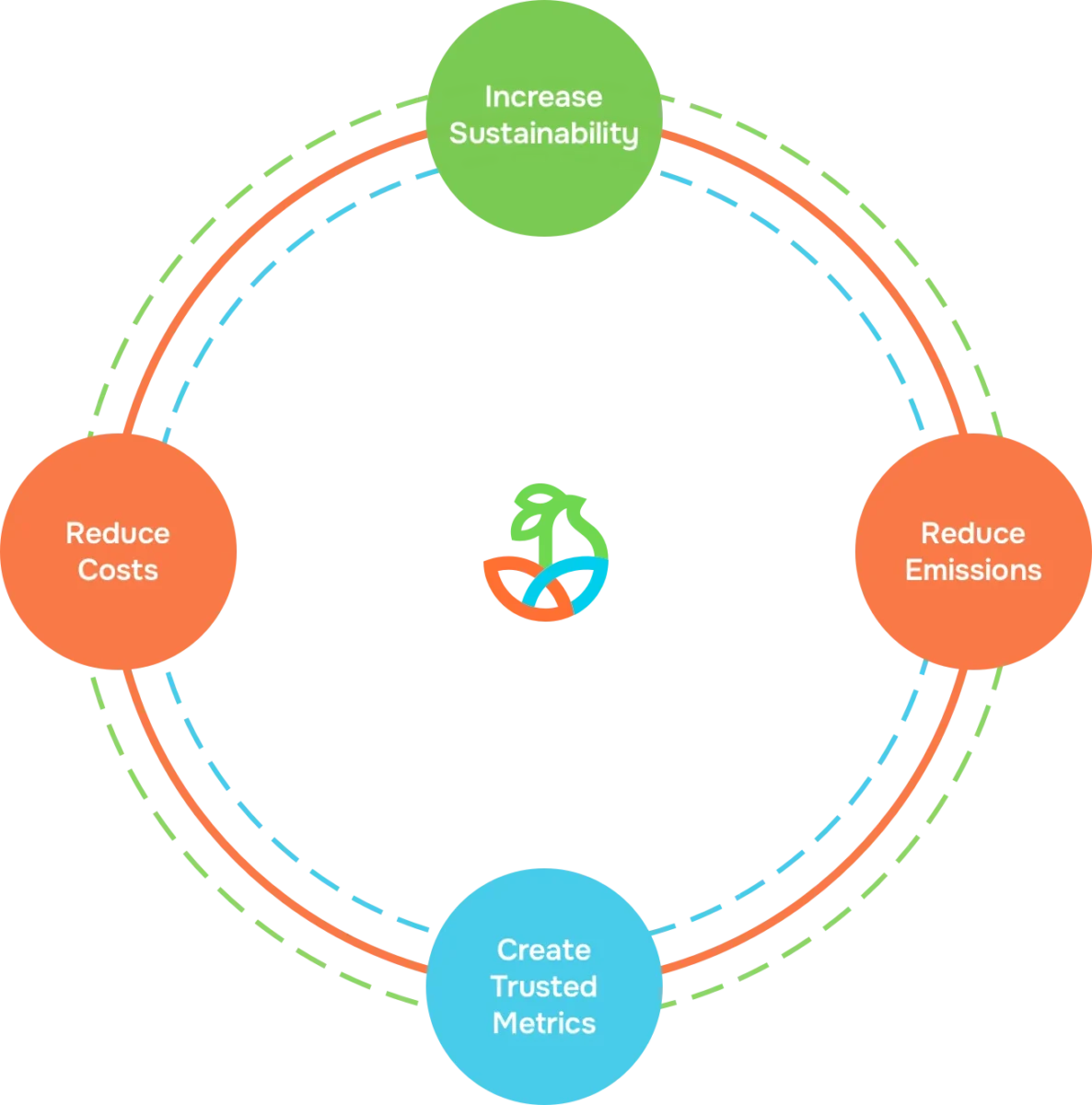

Driving the circularity of poultry waste management with our

industry-changing Manure-as-a-Service™ offering, Poulterra processes litter into higher-value sustainable products, reducing Scope 1, 2, and 3 emissions, cost, and environmental risk.

A win-win for poultry farmers, the environment, and the economy.

Better for Poultry.

Better for the Environment.

By harnessing the power of nature and the circular economy, Poulterra is setting new, unprecedented standards for sustainability in poultry.